Suparna Sen

Department of Biosciences and Bioengineering

Indian Institute of Technology Guwahati, Guwahati-781035

Email: suparnasen.08@gmail.com, ssen23@rnd.iitg.ac.in

Introduction: The need for cleaner energy

“Clean energy” or “carbon-free energy” allows us to generate power without greenhouse gas emissions, helping to combat climate change. Climate change, driven by human activity, is causing dramatic shifts in Earth’s temperatures and weather patterns, leading to droughts, severe fires, and other natural disasters. The burning of fossil fuels for energy is the largest contributor to climate change, responsible for over 75% of global greenhouse gas emissions. To avoid the worst impacts, emissions must be halved by 2030 and reach net zero by 2050, necessitating a shift from fossil fuels to clean, renewable energy sources like solar, wind, and hydropower, which emit little to no greenhouse gases [1]. While fossil fuels still dominate global energy production, renewable energy is rapidly growing, with projections showing it could supply 43% of global electricity by 2030. Although renewable energy is currently supplemented by carbon-based sources due to its variability, advancements in energy storage and infrastructure are expected to enable clean energy to fully replace fossil fuels [2].

Biofuels on the rise: The future of clean transportation

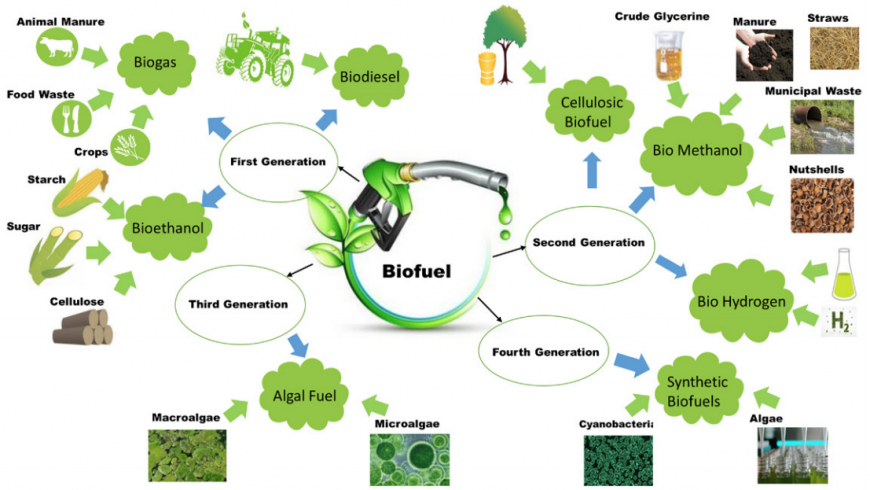

“Biofuels” typically refer to liquid fuels and blending components derived from biomass feedstocks. They can also include methane from landfill gas, biogas, and hydrogen produced from renewable resources. While most biofuels are used in transportation, they can also serve as fuels for heating and electricity generation. Biomass-derived fuels may qualify for government programs that promote or mandate biofuel usage [3].

The terminology for biofuels varies across government legislation, incentive programs, and industry marketing. For instance, fuel names may include prefixes like “bio” (e.g., biodiesel, biojet) or terms such as “advanced,” “alternative,” “clean,” “green,” “low-carbon,” “renewable,” or “sustainable” (e.g., sustainable aviation fuel). Definitions for these biofuels may differ depending on the context, with government programs often having distinct criteria compared to industry standards. Global demand for biofuels is set to grow by 41 billion litres, or 28%, over 2021-2026 in the main case [4].

The U.S. Energy Information Administration (EIA) publishes data on four major categories of biofuels that qualify for the federal RFS Program:

- Ethanol – an alcohol fuel blended with petroleum gasoline for vehicles; accounted for the largest share of U.S. biofuel production (82%) and of consumption (75%) in 2022 [5].

- Biodiesel – a biofuel usually blended with petroleum diesel for consumption; accounted for the second-largest share of U.S. biofuel production (9%) and of consumption (9%) in 2022 [6].

- Renewable diesel – a fuel chemically similar to petroleum diesel fuel used as a drop-in fuel or a petroleum diesel blend; percentage share of total U.S. biofuel production was about 8% and for consumption about 9% in 2022 [6].

- Other biofuels – include renewable heating oil, renewable jet fuel (sustainable aviation fuel, alternative jet fuel, and biojet), renewable naphtha, renewable gasoline, and other emerging biofuels that are in various stages of development and commercialization [7].

What is syngas?

Syngas or “synthesis gas” is generated after the gasification of carbon-rich biomass and consists of a mixture of H2, CO, and CO2 that could be used as a potential intermediate in the conversion of biomass into fuel. In some industrial settings (steel milling, petroleum refining, etc.), large amounts of waste gas with syngas-like compositions are produced.

The production of fuels from syngas relies on the Fischer-Tropsch (FT) process, a series of chemical reactions converting CO and H2 into liquid hydrocarbon. The process is unpopular because the equipment is expensive and has high operating and maintenance costs. However, a more sustainable alternative is the use of microbes as catalysts for syngas conversion to biofuels by a process termed syngas fermentation.

The science of syngas fermentation

Syngas fermentation represents a breakthrough in biofuel production. It involves a three-phase system: a gaseous syngas mixture, a liquid nutrient solution, and microbial cells suspended in the fermentation broth. Microbes, particularly acetogenic bacteria, act as biological catalysts, converting the CO and H₂ in syngas into valuable products such as ethanol, butanol, acetic acid, and methane [8]. Some of the microorganisms involved include Clostridium sp. P11, C. ljungdahlii, C. woodii, C. thermoaceticum, and C. carboxidivorans P7 [9].

However, syngas fermentation faces challenges such as poor mass transfer of gas into the liquid phase, low microbial cell concentrations, and relatively low productivity. Recent advancements, including genetic engineering of the microbes, are addressing these issues, enhancing their efficiency and adaptability for large-scale biofuel production.

Waste to energy: The environmental benefits

The world faces two critical challenges: dwindling fossil fuel reserves and improper waste management. As industrialization and population growth continue, the need for sustainable waste-to-energy solutions becomes ever more pressing. Municipal solid waste (MSW), forecasted to reach 2.6 billion metric tonnes by 2030, represents a continuous source of combustible materials such as plastics, organics, and textiles. Gasification of MSW can generate syngas and hydrogen, which can then be converted into biofuels, providing a renewable energy source while simultaneously reducing landfill waste.

Waste-derived fuels are gaining attention as alternative energy sources in both developed and developing countries, including the U.S., UK, India, Indonesia, and Thailand. By converting waste into energy, these technologies align with the 7th Sustainable Development Goal (SDG): affordable and clean energy. Processes like gasification, pyrolysis, and combustion are being optimized to transform refuse-derived fuel (RDF) into cleaner energy. Co-gasification, which combines RDF with biomass or biochar, has been shown to improve gas yield and reduce tar formation, making it a promising solution for sustainable energy production.

Conclusion: Paving the Way for Cleaner Energy

Syngas fermentation stands at the forefront of the biofuel revolution. By harnessing the power of microorganisms to convert waste into valuable biofuels, this technology not only provides an alternative to fossil fuels but also addresses critical environmental challenges. As advancements continue in microbial engineering and fermentation technologies, syngas fermentation is poised to play a significant role in the future of clean energy, paving the way for a more sustainable and carbon-free world.

Acknowledgements

The author acknowledges the financial support from SERB, DST, Govt. of India in the form of a National post-doctoral fellowship (NPDF, PDF/2022/001568) to her.

References:

[1] Jeswani, H.K.; Chilvers, A. and Azapagic, A. (2020). Environmental sustainability of biofuels: a review. Proc Math Phys Eng Sci. 476(2243):20200351. doi: 10.1098/rspa.2020.0351.

[2] Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N. and Valdez, R. (2022). A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability. 14: 4792. https://doi.org/10.3390/su14084792

[3] Liu, Y.; Cruz-Morales, P.; Zargar, A.; Belcher, M.S.; Pang, B.; Englund, E.; Dan, Q.; Yin, K. and Keasling, J.D.J.C. (2021). Biofuels for a sustainable future. Cell. 184: 1636-1647.

[4] Korberg, A.D. (2021). From the production to the utilisation of renewable fuels–pathways in an energy system perspective. Aalborg Universitetsforlag. https://doi.org/10.54337/aau422931426

[5] Edeh, I. (2021). Bioethanol Production: An Overview. IntechOpen. doi: 10.5772/intechopen.94895

[6] Bezergianni, S. and Dimitriadis, A. (2013). Comparison between different types of renewable diesel. Renewable and Sustainable Energy Reviews. 21: 110-116.

[7] Sen, S.; Malakar, C.; Banik, B.; Devi, N.B. and Pakshirajan, K. (2024). Drop-In Biofuel Production Using Fungi. In: Brar, S.K., Osorio Gonzalez, C.S., Soccol, C.R., Saini, R. (eds) The Microbiology of the Drop-in Biofuel Production. Biofuel and Biorefinery Technologies, vol 15. Springer, Cham. https://doi.org/10.1007/978-3-031-61637-2_7

[8] Daniell, J.; Köpke, M. and Simpson, S.D. (2012). Commercial biomass syngas fermentation, Energies, 5(12): 5372-5417; https://doi.org/10.3390/en5125372

[9] Yasin, M.; Cha, M.; Chang, I.S.; Atiyeh, H.K.; Munasinghe, P. and Khanal, S.K. (2019). Syngas fermentation into biofuels and biochemicals, In: Biomass, Biofuels, Biochemicals, (Eds.) Pandey et al., Academic Press. pp. 301-327.

N.B- The picture has been taken from this url- https://commons.wikimedia.org/wiki/File:Types_and_generation_of_biofuels.png