Dr Sophia M. Gogoi

Assistant Professor, Department of Veterinary Microbiology,

College of Veterinary Science, A.A.U., Khanapara, Guwahati-22

e-mail– sophiagogoi@gmail.com, Ph No. 9706072570

Energy resource depletion is a grave crisis threatening the modern world. The burgeoning human population coupled with the subsequent increase in energy consumption has brought us to the brink of exhausting the non-renewable resources such as natural gas, oil and coal. Another issue that has been raising alarm in the context of the global energy sector is the fact that combustion of fossil fuels result in emission of major green house gases (GHG), which have deleterious effects on the environment. The need for alternative sources of energy is, therefore, well-recognized and over the years, significant discoveries and inventions have been made in this aspect. However, some believe that a single alternative may not be a sustainable solution for reducing or substituting the reliance on fossil fuels. A combination of various carbon-neutral and renewable energy sources including existing technologies like solar, wind etc. will be needed to suffice our future energy demands. Renewable energy technologies have the potential to not only meet our energy needs but can also play a significant role in mitigating climate change by reducing GHG emissions. In this scenario, Microbial fuel cells (MFC) technology is a highly attractive advancement and can play an important part. MFCs harness the energy produced from microbial metabolism and in a nutshell convert biochemical energy to electrical energy. MFC technology is environment-friendly as it can operate at ambient conditions and produces pollution-free energy

The idea of ‘animal electricity’ can be traced back to the 18th century, when Galvani carried out experiments with frog legs. However, it is Potter who is attributed to have conceived the concept of utilizing microbes for generation of electricity in 1911. Different workers since then have explored further concepts and practical developments. Notable among these are Cohen’s 35-unit setup in 1931, catalyst investigations in the 60’s and the work on synthetic mediators during 80s-90s, which led to the development of the so-called “analytical MFC”. In recent years, several studies have been carried out towards the enhancement of design and electrode materials to boost up the performance of MFCs.

MFC DESIGN

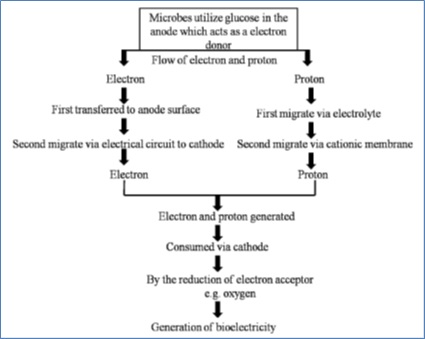

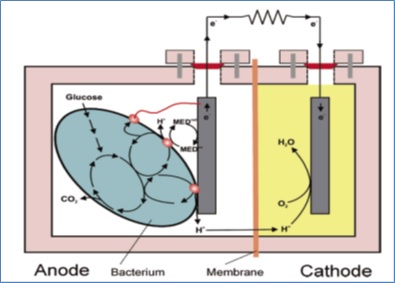

A typical MFC consists of several components primarily divided into two chambers namely the anodic and cathodic chambers. In general, anoxic conditions are maintained in the anodic compartment, whereas the cathode can either be suspended in aerobic solutions or exposed to air. These chambers are again separated by a proton exchange membrane (PEM). The microbes reside in the anodic chamber and are provided with a favorable substrate, anaerobic degradation of which results in release of electrons and protons. The electrons are then transferred to the anodic surface and then transported to the cathode via external circuit. The protons generated are selectively passed through the exchange membrane. Both these products get consumed in the cathode by reduction of soluble electron acceptor, such as oxygen or hexacynoferrate and acidic permanganate. Most suitable electron acceptor for an MFC is Oxygen because of its high oxidation potential, availability, sustainability and the lack of a chemical waste product (water is formed as the only end product). For accelerating the oxygen reduction on the surface of the cathode, one of the commonly used metals is platinum because of its excellent catalytic ability. Since platinum is expensive, it is a major hurdle in the MFC application and economic viability. Replacing platinum with cheaper alternatives, such as manganese dioxide, iron and cobalt-based materials can, therefore, improve the cost effectiveness while ensuring the efficiency.

Fig. 1 Schematic representation of the production of bioelectricity from microbes

(Chaturvedi and Verma, 2016)

Fig 2. Operating principles of a MFC (Logan et al., 2006)

A wide range of substrates has been employed in MFCs over time. The choice of substrate is crucial because it influences both the integral composition of the bacterial community in the anode biofilm, and also the MFC performance. In the early stages of development of this technology, low molecular weight substrates were employed. Examples include carbohydrates like glucose, fructose, sucrose and trehalose; organic acids like acetate, lactate, succinate and malate; alcohols like ethanol and methanol, and inorganic compounds like sulfate. Later on starch, cellulose, dextran, molasses, chitin and other such complex substrates were also employed. Over and above, domestic wastewater, waste sludge, fruit and vegetable wastes etc. have also been tested for bioelectricity production using MFCs.

In a similar manner, for the construction of MFCs different microorganisms have been used since many microorganisms are known to possess the ability to transfer the electrons derived from the metabolism of organic matters to the anode. Initial studies on dissimilatory metal reducing bacteria such as Geobacter and Shewanella species helped to understand electron transfer by bacteria to electrodes. Biochemical and genetic characterizations indicated involvement of outer-membrane cytochromes in exogenous electron transfer. Further studies led to the discovery of nanowires, which appear to be directly involved in extracellular electron transfer. Nanowires are conductive, pilus-like structures, identified in Geobacter sulfurreducens PCA, Shewanella oneidensis MR-1, a phototrophic cyanobacterium Synechocystis PCC6803 and the thermophilic fermenter Pelotomaculum thermopropionicum, and this finding has added a whole new dimension to this field of study.

Studies have demonstrated that MFCs operated using mixed cultures achieve substantially greater power densities than those with pure cultures. Mixed cultures or microbial consortia have been shown to be efficient than pure strains which suffer from limitations like necessity for sterile conditions, which leads to high costs. However, some studies have shown that pure cultures of Geobacter sulfurreducens could produce near or greater than maximum power of mixed species biofilms. This bacterium is one of the most extensively studied microorganisms and is capable of high current densities in a MFC. It belongs to class of microbes referred to as electricigens, a term which is used for describing microbes that completely oxidize organic compounds with direct electron transfer to the anode of the MFC. Different terms have been proposed for microorganisms that have the ability to transfer electrons to an electrode, viz. anodophiles, exoelectrogens , electrogenic microorganisms, anode-respiring bacteria and electrochemically active bacteria (EAB).

TYPES OF MFC

With the advances in the MFC technology, different types of MFCs have been developed.

- Two-compartment MFC: It represents the classical design of a MFC consisting of dual chambers separated by an ion exchange membrane.

- Single-compartment MFC: This involves only the anodic chamber along with an air cathode to which the protons and electrons are transferred.

- Stacked MFC: To increase the overall system voltage, MFCs can be stacked connected with each other in series or in parallel connection

- Mediator-less MFC: Mediator less MFCs eliminate the potential use of exogenous mediator compounds. In this type of MFCs, EABs are employed which mediate the transfer of electrons from the substrate (electron donor) to the electrode.

- Membrane-less MFC: In this type, the PEM is absent and are mostly preferred in cases of waste water treatment applications.

- Catalyst coated electrode MFCs: Here chemicals such as polyaniline are coated on the surface of the electrodes to assist in the transfer of electrons to the electrode and thus to increase their efficiency.

- Sediment-type MFCs: This type of MFC involves insertion of one of the electrode (anode) in anaerobic sediment consisting of both, the organic substrates and the microbial community and is connected to the cathode which is placed in aerobic water.

APPLICATIONS:

The key prospect of the MFC technology is the production of bioelectricity by the utilization of organic carbohydrate substrates from biomass obtained from agricultural, industrial and municipal wastes. MFCs have also been applied in Bio-battery concept for recharging appliances and devices requiring small voltage. Different modifications have been inculcated into the primary and basic design of a MFC thereby providing a base for further construction of new ideas and applications.

In the long run, microbial fuel technology also holds promise as an ideal solution to the long-lasting question of waste water management. Several researchers have studied MFCs as reactors for waste water treatment for replacing the existing energy-demanding bioreactor (such as an activated sludge system). This could lead to a sustainable system decreasing society’s need to invest substantial amounts of energy in such treatments. Moreover, in the field of biosensors, MFCs have been used to power such devices; particularly in river and deep-water environments where replacing batteries routinely is impractical. MFC technology based biosensors can be utilized for measuring the biological oxygen demand of different treatment plant effluents and also for evaluating the pollutant level of several waste water effluents.

Further, MFC technology for the production of bioelectricity is being used for various applications both at industrial and research levels. One of the earliest example of microbial metabolism working in a real practical application is perhaps that of Gastrobot (aka Chew-Chew train), a 3- wagon toy train in which an artificial stomach filled with E. coli metabolising sugar was used to feed into a stack of biotic/chemical fuel cells powering the train’s motors and pumps. EcoBot-I was the first robot which was reportedly powered only by MFCs fed with glucose without using batteries, solar cells or any other form of conventional power source. Another example is the first demonstration of a self sustainable MFC stack which generated sufficient energy to power its own feeding and hydration pumps and thereby sustaining long-term operation.

CONCLUSION:

MFC is a promising technology and is rapidly evolving to expand its horizon. The most immediate and useful application of MFCs probably lies in waste water treatment and environmental sensors but opportunities for other applications exist and humans have probably touched only the surface of MFC capabilities. With enhanced understanding of microbial metabolism and genomics, better exoelectrogens can be discovered leading to newer applications in areas like nano-electronics. Though MFC technology suffers from major drawbacks like low power output, scaling up issues etc., it may still play a role in the future for the next generations and our planet. For this to be realized, a well-coordinated approach involving different scientific fields like electrochemistry, engineering and microbiology is needed to pave the way for the development of several potential practical applications of MFC.

REFERENCES:

- Akshay D. Tharali; Namrata Sain and W. Jabez Osborne (2016). Microbial fuel cells in bioelectricity production. Frontiers in Life Science. 9(4): 252-266. DOI: 10.1080/21553769.2016.1230787.

- Chaturvedi, V and Verma, P. (2016). Microbial fuel cell: a green approach for the utilization of waste for the generation of bioelectricity. Bioprocess. 3: 38. DOI 10.1186/s40643-016-0116-6.

- Logan BE and Regan JM (2006) Microbial fuel cells: challenges and applications. Sci. Technol . 40: 5172–5180.

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schroder, U.; Keller, J., Freguia, S.; Aelterman, P.; Verstraete, W. and Rabaey, K. (2006). Microbial Fuel Cells: Methodology and Technology. Environmental Science & Technology , 40: 5181-92

-

Santoro, C.; Arbizzani, C.; Erable, B. and Ieropoulos, I. (2017). Microbial fuel cells: From fundamentals to applications. A review. Journal of Power Sources. 356: 225-244.