Dr. Manashi Das Purkayastha

Assistant Professor

Department of Horticulture

Assam Agricultural University

Dr. Manashi Das Purkayastha (B.Sc., Gold medalist; M.Sc., Gold Medalist; Ph.D., Food Engineering & Technology, Tezpur University), is currently working as an Assistant Professor at Assam Agricultural University (AAU), Jorhat, Assam. She is the founding faculty of the Food Science & Technology Programme (Department of Horticulture) at AAU; guided several Post-graduate students (including foreign students under international scholarship) and presently many are working under her supervision (as major/minor/supporting advisor); currently involved with numerous administrative responsibilities/Outreach activities as Resource person/ speaker/External examiner/paper-setter of numerous Food Technology & Nutrition courses. Her research interest encompasses protein chemistry, bioactive nutraceuticals, nanomaterials and biopolymers for food and industrial applications. Accolades garnered by her includes: ICAR-World Bank funded NAHEP overseas training award cum fellowship for training at University of Queensland, Australia; DST-INSPIRE fellowship for pursuing Ph.D. (selected for both Junior Research Fellowship and Senior Research Fellowship) (2010-2014); UGC-funded Post-Graduate Merit Scholarship for University Rank holder (2008-2010); Prof. Buta Ram Memorial Award from Zoological Society of Assam; qualified ICAR-NET (Food Technology) and GATE (XL-Life Science with Food Technology). Administering two DBT-funded research projects (net grants are Rs. 1.24 crores and 42.15 lakhs, respectively) as PI and one as Co-PI (net grant is one crore); life membership of AFST(I) and authorship of a number of research articles in journals of international repute and a few review/book chapters.

Salient technologies developed by Dr. Manashi Das Purkayastha & her research group for entrepreneurs/industries and translational research outcomes/technology transfer

- Quick rehydrating, low calorie rice-based composite pasta having high protein content (~1.18-1.30 times higher than the conventional wheat pasta) and the most desirable feature of low in vitro starch digestibility and calorific values (~1-1.2 fold reduction). The product can be readily rehydrated in hot or boiling water (within 3-5 minutes) by pour-over preparation like “cuppa noodles”, and is very convenient for busy urban-life and on-the-go portable meals (P. Devi & M. Das Purkayastha, 2017)

Rice composite pasta (before rehydration) Rice composite pasta (after rehydration/cooking)

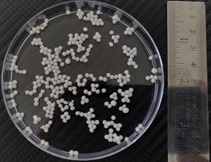

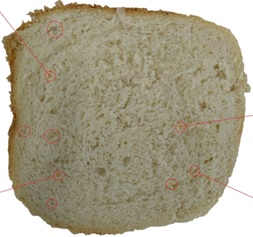

- Vitamin-encapsulated protein-mucilage beads as an additive and fortificant for daily staple foods (e.g., bread). These tiny beads are loaded with strong antioxidative health benefiting nutrients, which are otherwise bitter-tasting, thermo-labile and poorly absorbed in the body. Encapsulating them within protein or mucilaginous matrix has improved their stability in extreme pH, high cooking temperature and sustained release during in vitro digestion, and also masked the bitter taste of the loaded compound. Addition of these vitamin-rich protein beads in daily staple foods (e.g. bread, chapatti, etc) will prove to be an excellent vehicle for delivering the deficient vitamins (antioxidant against several diseases) to a very large numbers of people, in particular the widespread at-risk population all at once (B. Pramodini, F. Dutta, S. Kalita & M. Das Purkayastha, 2017).

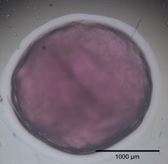

Empty beads made of edible protein-polysaccharide blend

Beads loaded with antioxidative, anticancerous natural pigment (betalains)

Beads loaded with antioxidative, anticancerous natural pigment (betalains)

Beads loaded with antioxidative vitamin E to mask its bitter taste

“Functional Bread” fortified with encapsulated vitamin E (marked as red circles) for dietary consumption

Ready-to-reconstitute Elephant apple juice powder

- Spray-dried Elephant apple juice with no added sweetening agent: Elephant apple is a wild minor fruit of North East India and is bestowed with numerous health benefits like anti-diabetic, anti-rheumatic, etc. However, the urban population fails to receive these benevolent fruit due to its endemic nature and non-availability of its processed products (except pickle). A ready-to-reconstitute spray-dried juice powder from Elephant apple was developed using whey, which has taste and flavour similar to the natural juice. The product does not contain any artificial sweetening agent and is rich in soluble protein (suitable for athletic drinks) (U. Borah & Das Purkayastha, 2019).

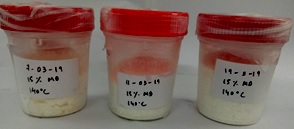

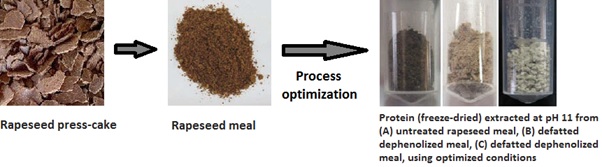

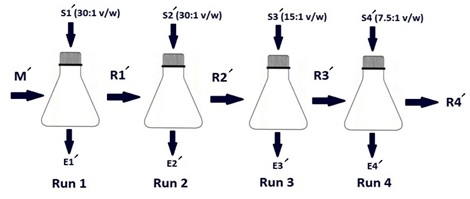

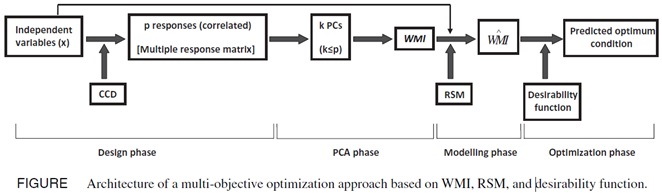

- Multi-stage batch extraction Scale-up of protein extraction from rapeseed press-cake (a major waste of oilseed industry): Rapeseed protein, though highly nutritious, is less profitable than soya protein, because of its dark colouration and low yield. So, a methodical optimization strategy for industrial scale-up of multi-stage batch extraction process has been successfully developed. The process also includes the sequential procedure to remove the toxic compounds (anti-nutrients) from rapeseed press-cake, which was effectively used in biodiesel to retard oxidation. The major findings of this statistically designed optimization procedure have been published in several renowned international journals (enclosed in the list of publication). The final product is a white coloured high quality edible protein, with good functional properties for food applications ( Das Purkayastha & C. L. Mahanta, 2014).

Fig. Cross-flow extraction in four stages [S(n)’= extractant solvent:meal (v/w) ratio of stage n; M’= Partially dephenolized rapeseed meal; R(n)’= Residual solid from stage n; E(n)’=Extract from stage n; water was used as extractant in Run 1, whereas alkaline solution of pH 11 (with 0.097M NaCl and 0.4% sodium sulfite) was used as extractant in the remaining stages; extraction time for each run= 1h]

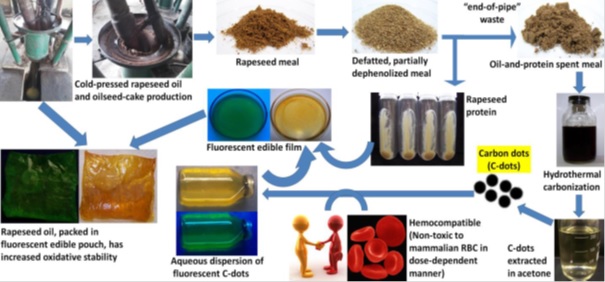

- Highly fluorescent carbon nanoparticles from plant source for anti-counterfeiting application: Fluorescent carbon nano-dots were prepared from oil-and-protein spent rapeseed waste, which practically has no utility. The carbon-dots were prepared by hydrothermal treatment following the guidelines of green chemistry, and displayed strong fluorescence emission under UV light, haemo-compatibility with mammalian RBCs and good antioxidant capacity (scavenging free radicals and reactive oxygen species). The potential function of this plant waste-derived fluorescent carbon nanoparticle was evaluation in food packaging film. This organic nanoparticle can be easily incorporated in variety of products for preventing forgery, such as currency notes, swipe cards, etc. for trademark or hologram printing ( Das Purkayastha & C. L. Mahanta, 2014).

- Development of a low-cost 2-stage microfiltration system for increasing the shelf-life of tender coconut water, without any heat treatment: Microfiltration of coconut water was found to be an alternative to thermal sterilization. Concerted effect of microfiltration and L-ascorbic acid (Vitamin C) addition proved to be a better method for processing coconut water than microfiltration alone. The processed coconut water was found to be stable and acceptable up to 1 month of aseptic storage at refrigerated condition (M. Das Purkayastha, C. L. Mahanta & M. K. Chaudhuri, 2012).

Fig. Experimental set-up for low-cost pressure filtration of coconut water (Indian Patent filed for)

- Resistant starch-rich ready-to-constitute breakfast mix (with no added sugar or sweetening agent or artificial colourant): A gluten-free nutritious ready-to-reconstitute breakfast mix (convenient food) was prepared using makhana seed, wood apple pulp powder, banana and malted mung bean powder, which does not require any cooking and can be easily reconstituted in hot water or milk for consumption. All these ingredients are well-reported to be bestowed with multifarious health benefits, especially malted mung bean. The mix was processed to enhance the amount of resistant starch which prevents the glycaemic index from rising up rapidly after its consumption, maintains the satiety (a feeling of fullness or anti-hungerness) for longer duration and was found to be naturally sweet, without the addition of any extraneous sugar or sweetening agent (J. Dei-Koomson, U. Kalita & M. Das Purkayastha, 2018).

Fig. Wood apple pulp powder, Makhana seed flour, malted mung bean powder and banana flour used for making Ready-to-constitute breakfast mix

Fig. Final formulation of breakfast mix in dry form and rehydrated form (in hot water).

[The prepared gruel does not have any exogenous sweetening or colouring agents]